It’s been a while since my last CNC update because I have been very busy with work, but I have made a lot of progress and a few steps back.

I was able to get all 3 axises put together and aligned pretty well. The only real problem is that my Z axis stepper is not going to have enough torque and it has too much run out in the stepper motor. but for testing it is fine.

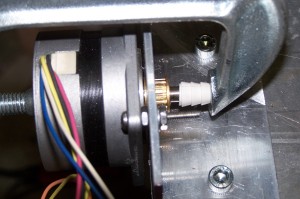

First I wanted to explain how I am coupling my motors to the lead screw, AKA all thread 🙂

I took a vacuum TEE that I had and cut the barb off of one end.

This was too small to just slide onto the shaft of the stepper so I had to press it on using a C-clamp. This makes for a very tight fit. Then I score the barbs parallel to the shaft to give it teeth that can bite into the rubber tubing to keep it from slipping. I then press a short piece of tubing onto the barb and then onto the leadscrew. If needed you can add a tie wrap to secure the tubing even more. Here is a picture of how I pressed it on the stepper.

Here is a video of all 3 Axises running at the same time. I am using my arduino to run this test because I fried my buffer chips in by breakout board! That is fine, I will build something better anyway.

Here is a picture of my Z axis flange nut I built. It is hand filed to a press fit so that I can adjust it to align.

I have not put any anti backlash devices on these yet, but I have a design in mind for some.

One Response to CNC Update 7: Simultaneous 3 Axis Motion

You must log in to post a comment.